Manage Workshops Efficiently in the Cloud with Ed & Ted – Get it Done!

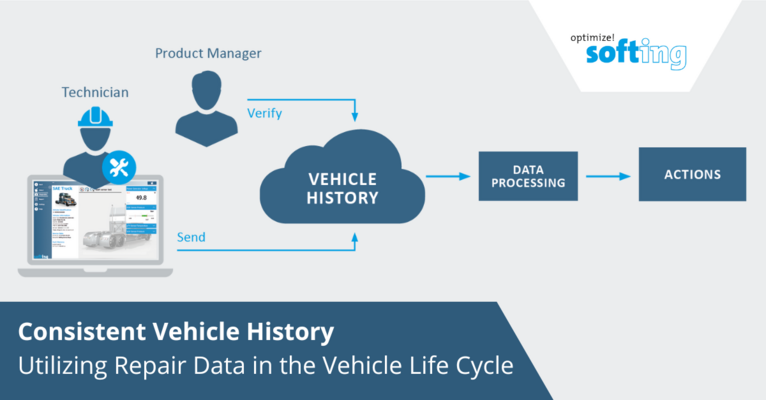

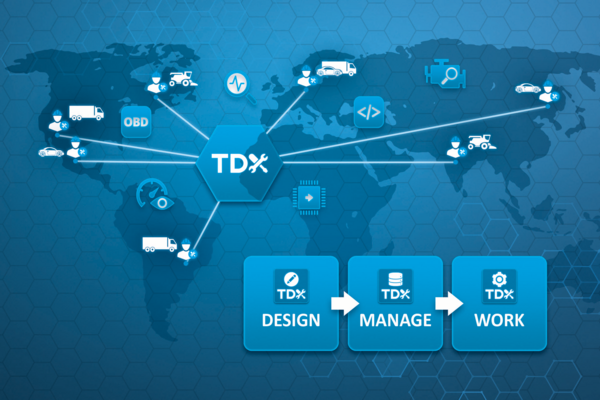

In aftersales, faults and problems need to be identified and resolved as quickly as possible. The service tester is an indispensable tool for workshop employees and mobile service teams when localizing faults, troubleshooting and commissioning components and vehicles. With Softing TDX, all the benefits of digital transformation in aftersales can be exploited by storing and linking data centrally.