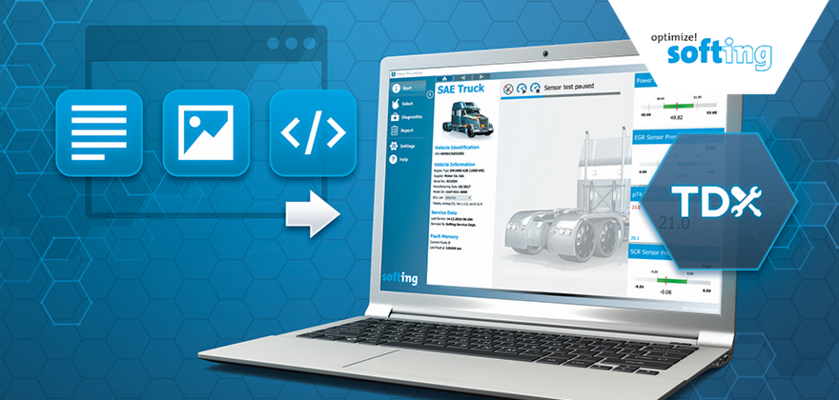

Design Templates in high-end quality reduce the effort involved in tester implementation

Users make high demands on the interface and the operating concept of today’s diagnostic testers. An intuitive user interface reduces both the time required for users to familiarize themselves with the tester and the usage time for diagnostic tasks during daily work. Creating elaborate, platform-independent testers is complicated and takes a lot of time – time that is often simply not available. Support from suitable editor tools, cross-platform development as well as prefabricated design templates can help. The effort involved in creating anything from individual functions to a complete diagnostic tester in a bespoke design is thus reduced considerably.